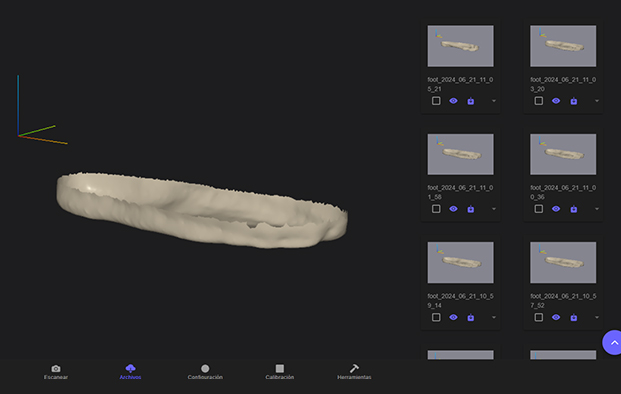

Digitise foot

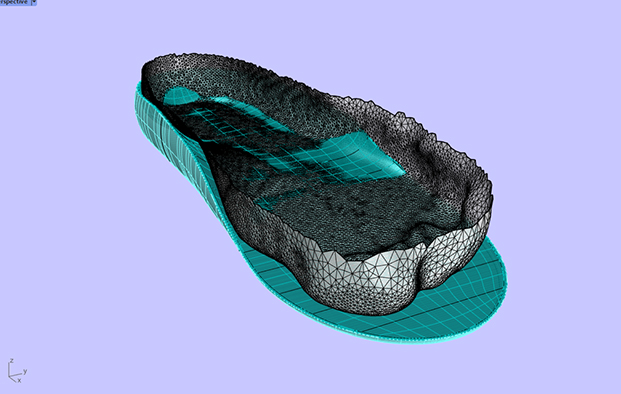

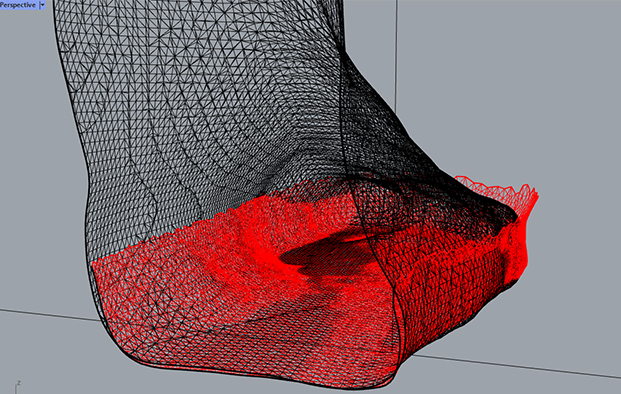

Start your shoe making process by digitising the foot as the basis for the last. It will be your blank canvas to create any shoe.

Functionalities

- Lightweight technology, easy to transport and install.

- Plug & play solution that connects via USB to any Windows computer.

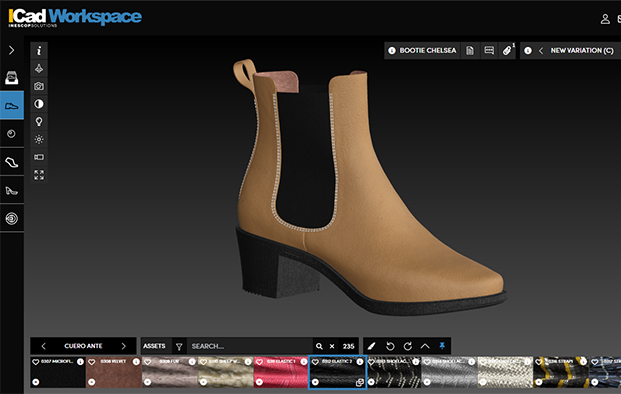

- Connected and compatible with other Icad solutions.

- Fast and accurate system, which guarantees a faithful reconstruction of the foot.

- Captures a large number of measurements automatically.

- Easy positioning of the foot with the scanning process always visible.