Discover the

Icad advantages

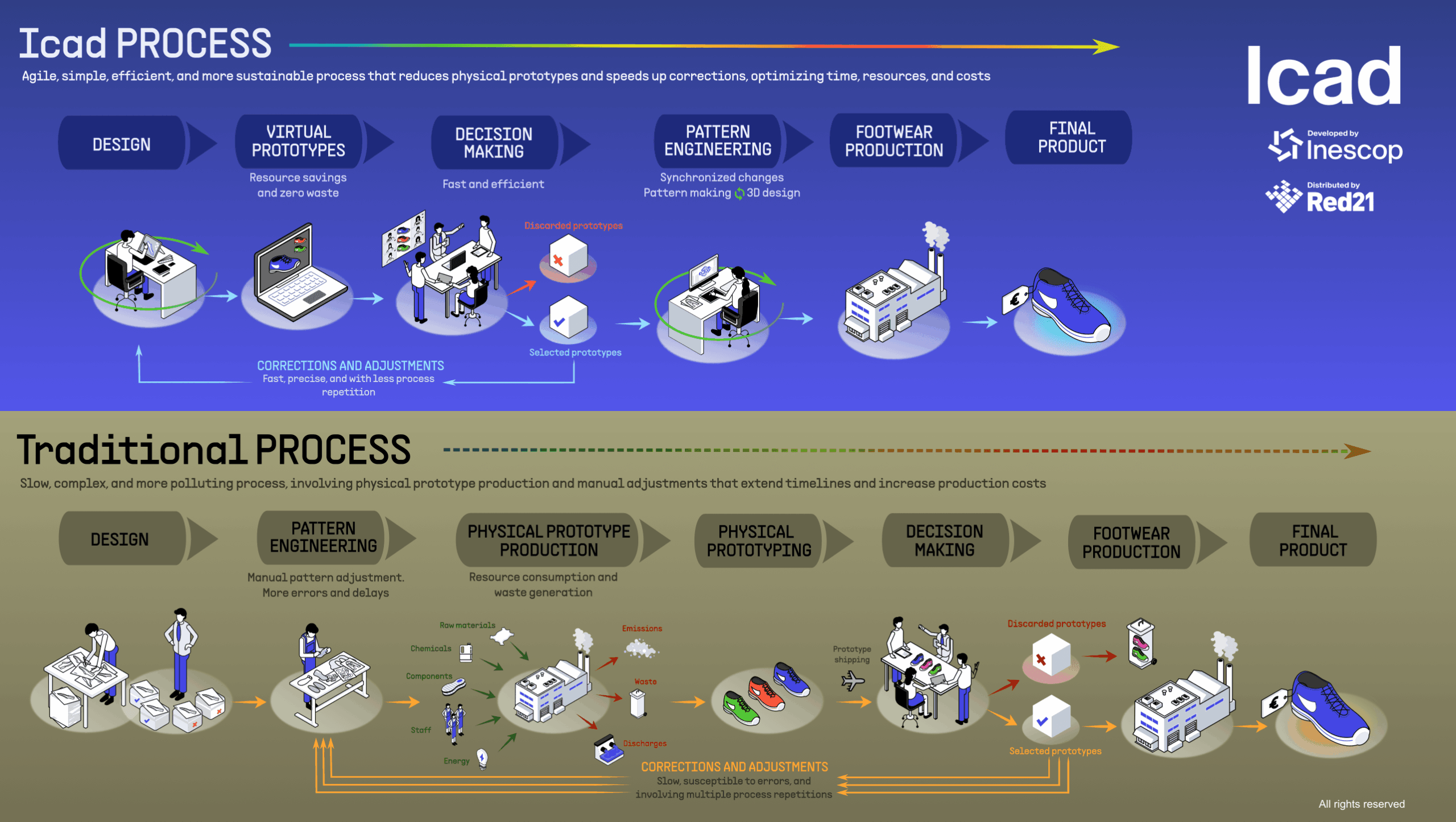

In footwear development, the difference between a traditional process and a digital one is much more than a matter of which tools are used.

It's the difference between saving resources, gaining agility, and reducing unnecessary steps, or spending more, losing more time, and repeating processes.

Icad is accuracy fewer errors optimization fast decisions competitiveness

Every tool in the Icad Universe, from 3D design, 3D/2D pattern making, and consumption calculations to technical documentation, is designed to reduce errors and maintain total consistency throughout all stages of development.

The direct connection between 3D and 2D environments ensures that every modification is reflected in the other environment, without deviations or loss of information. This means that designers and pattern makers can always work with up-to-date data, avoiding inconsistencies and rework.

The result: technically accurate, perfectly scalable, production-ready models, with all technical documentation generated automatically and reliably. More control. Higher quality. Greater confidence at every step of the process.

Every day I see how Icad Universe helps companies reduce errors thanks to its recision and accuracy, the result of a fully interconnected universe that maintains consistency across all departments involved in footwear creation.

With Icad Universe correction cycles are reduced and validation times are shortened.

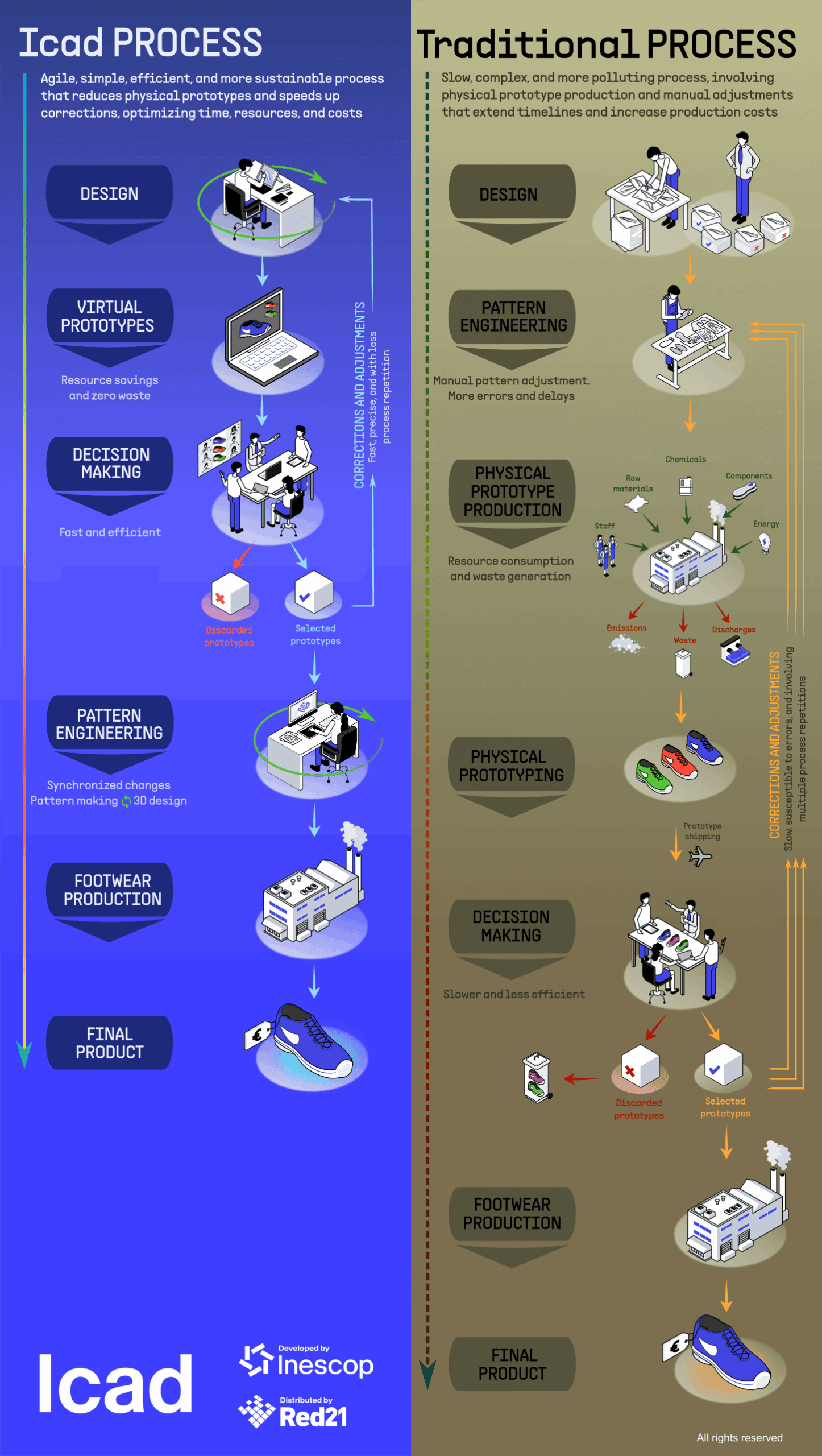

Teams can work simultaneously and see changes in real time, regardless of where they are in the world.

Each modification is immediately updated at all stages of the process, avoiding repetition, accumulated errors, and wasted time between departments. It is no longer necessary to redo patterns, resend files, or manufacture physical prototypes to review a model.

Decisions also become more agile: designers, pattern makers, product managers, and factories can evaluate a digital model together, make decisions in minutes, and move on to the next phase without waiting or physical shipments.

This not only speeds up development, but also improves communication and overall coordination between teams, reducing production times.

The result: 𝗮 𝗺𝗼𝗿𝗲 𝗮𝗴𝗶𝗹𝗲, 𝗰𝗼𝗻𝗻𝗲𝗰𝘁𝗲𝗱, 𝗮𝗻𝗱 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝗲 𝘄𝗼𝗿𝗸𝗳𝗹𝗼𝘄, where each step adds precision, speed, and consistency.

Implementing Icad Universe in the process not only improves efficiency but also reduces environmental impact.

The replacement of physical prototypes with virtual prototypes reduces the need to manufacture multiple versions of the same model for validation or adjustment. This translates into direct savings in resources such as raw materials, components, chemicals, and energy, as well as reducing work time and resource consumption associated with each iteration.

Moreover, with Icad, teams can review, modify, and validate models in real-time from anywhere in the world, eliminating the need for frequent travel and physical prototype transport, thus reducing pollution from travel and both national and international logistics.

All of this prevents the generation of waste, discharges, and emissions associated with the manufacturing and transportation of physical prototypes, as well as other manual tasks and repeated processes. This transition not only reduces the environmental impact but also lowers the costs related to managing and treating those wastes, improving the overall efficiency of the process.

Furthermore, Icad allows for the calculation of the total carbon footprint of the models in kilograms of CO₂ equivalent, helping to monitor and evaluate the environmental impact of every design or production decision.

Having this information enables companies to act based on objective criteria, make decisions guided by data, and identify areas for improvement in material usage efficiency, thus promoting eco-efficient design and more responsible manufacturing practices.

Each digital validation represents a step toward a more responsible process: less resource consumption, less waste, and, ultimately, more sustainable production.

Digitizing not only streamlines processes but also transforms the way of creating, fostering a development model that is more respectful of the environment and aligned with the sustainability goals that should be central to any industry.

Icad boosts companies competitiveness by enabling them to develop their products with greater control, speed, and efficiency, strengthening their ability to respond to the demands of the global market. The implementation of Icad in the footwear creation process not only optimizes time and resources, but also 𝗶𝗻𝗰𝗿𝗲𝗮𝘀𝗲𝘀 𝗿𝗲𝘀𝗽𝗼𝗻𝘀𝗶𝘃𝗲𝗻𝗲𝘀𝘀 𝘁𝗼 𝗺𝗮𝗿𝗸𝗲𝘁 𝗰𝗵𝗮𝗻𝗴𝗲𝘀, allowing for quick adaptation of materials or model collections.

In addition, an interconnected and accurate digital flow strengthens communication between technical teams, enabling more effective coordination.

The result is a more competitive and sustainable working model that is prepared to face the challenges of an industry that demands constant 𝗶𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻, 𝗮𝗴𝗶𝗹𝗶𝘁𝘆, 𝗮𝗻𝗱 𝗲𝗻𝗳𝗶𝗿𝗼𝗻𝗺𝗲𝗻𝘁𝗮𝗹 𝗿𝗲𝘀𝗽𝗼𝗻𝘀𝗶𝗯𝗶𝗹𝗶𝘁𝘆.

Every tool in the Icad Universe, from 3D design, 3D/2D pattern making, and consumption calculations to technical documentation, is designed to reduce errors and maintain total consistency throughout all stages of development.

The direct connection between 3D and 2D environments ensures that every modification is reflected in the other environment, without deviations or loss of information. This means that designers and pattern makers can always work with up-to-date data, avoiding inconsistencies and rework.

The result: technically accurate, perfectly scalable, production-ready models, with all technical documentation generated automatically and reliably. More control. Higher quality. Greater confidence at every step of the process.

Every day I see how Icad Universe helps companies reduce errors thanks to its recision and accuracy, the result of a fully interconnected universe that maintains consistency across all departments involved in footwear creation.

With Icad Universe correction cycles are reduced and validation times are shortened.

Teams can work simultaneously and see changes in real time, regardless of where they are in the world.

Each modification is immediately updated at all stages of the process, avoiding repetition, accumulated errors, and wasted time between departments. It is no longer necessary to redo patterns, resend files, or manufacture physical prototypes to review a model.

Decisions also become more agile: designers, pattern makers, product managers, and factories can evaluate a digital model together, make decisions in minutes, and move on to the next phase without waiting or physical shipments.

This not only speeds up development, but also improves communication and overall coordination between teams, reducing production times.

The result: 𝗮 𝗺𝗼𝗿𝗲 𝗮𝗴𝗶𝗹𝗲, 𝗰𝗼𝗻𝗻𝗲𝗰𝘁𝗲𝗱, 𝗮𝗻𝗱 𝗲𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝗰𝗲 𝘄𝗼𝗿𝗸𝗳𝗹𝗼𝘄, where each step adds precision, speed, and consistency.

Implementing Icad Universe in the process not only improves efficiency but also reduces environmental impact.

The replacement of physical prototypes with virtual prototypes reduces the need to manufacture multiple versions of the same model for validation or adjustment. This translates into direct savings in resources such as raw materials, components, chemicals, and energy, as well as reducing work time and resource consumption associated with each iteration.

Moreover, with Icad, teams can review, modify, and validate models in real-time from anywhere in the world, eliminating the need for frequent travel and physical prototype transport, thus reducing pollution from travel and both national and international logistics.

All of this prevents the generation of waste, discharges, and emissions associated with the manufacturing and transportation of physical prototypes, as well as other manual tasks and repeated processes. This transition not only reduces the environmental impact but also lowers the costs related to managing and treating those wastes, improving the overall efficiency of the process.

Furthermore, Icad allows for the calculation of the total carbon footprint of the models in kilograms of CO₂ equivalent, helping to monitor and evaluate the environmental impact of every design or production decision.

Having this information enables companies to act based on objective criteria, make decisions guided by data, and identify areas for improvement in material usage efficiency, thus promoting eco-efficient design and more responsible manufacturing practices.

Each digital validation represents a step toward a more responsible process: less resource consumption, less waste, and, ultimately, more sustainable production.

Digitizing not only streamlines processes but also transforms the way of creating, fostering a development model that is more respectful of the environment and aligned with the sustainability goals that should be central to any industry.

Icad boosts companies competitiveness by enabling them to develop their products with greater control, speed, and efficiency, strengthening their ability to respond to the demands of the global market. The implementation of Icad in the footwear creation process not only optimizes time and resources, but also 𝗶𝗻𝗰𝗿𝗲𝗮𝘀𝗲𝘀 𝗿𝗲𝘀𝗽𝗼𝗻𝘀𝗶𝘃𝗲𝗻𝗲𝘀𝘀 𝘁𝗼 𝗺𝗮𝗿𝗸𝗲𝘁 𝗰𝗵𝗮𝗻𝗴𝗲𝘀, allowing for quick adaptation of materials or model collections.

In addition, an interconnected and accurate digital flow strengthens communication between technical teams, enabling more effective coordination.

The result is a more competitive and sustainable working model that is prepared to face the challenges of an industry that demands constant 𝗶𝗻𝗻𝗼𝘃𝗮𝘁𝗶𝗼𝗻, 𝗮𝗴𝗶𝗹𝗶𝘁𝘆, 𝗮𝗻𝗱 𝗲𝗻𝗳𝗶𝗿𝗼𝗻𝗺𝗲𝗻𝘁𝗮𝗹 𝗿𝗲𝘀𝗽𝗼𝗻𝘀𝗶𝗯𝗶𝗹𝗶𝘁𝘆.

Whatever your profile, we have your solution

Choose the option fits you best: